Watermark

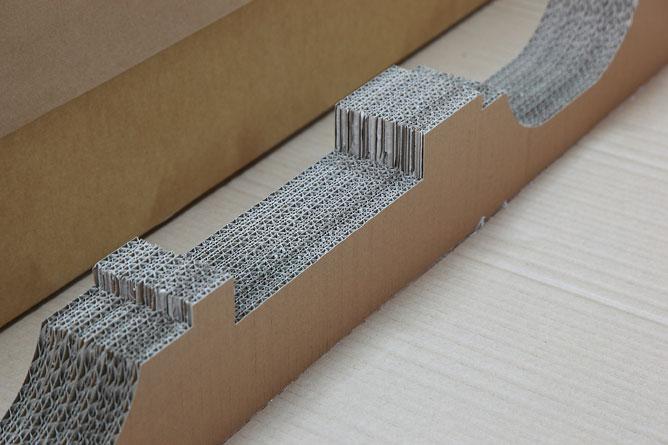

Solvent-resistant and Color-Adhesive Printing on Corrugated Board: Our printing process ensures that designs are resistant to solvents and adhere well to corrugated board, allowing for vibrant and long-lasting colors. The printed graphics remain intact without fading or smudging during handling or exposure to various environmental conditions.

Color Printing

Adding color and patterns to paper boxes enhances the visual appeal and perceived quality of product packaging. This is commonly employed in commercial packaging and gift boxes.

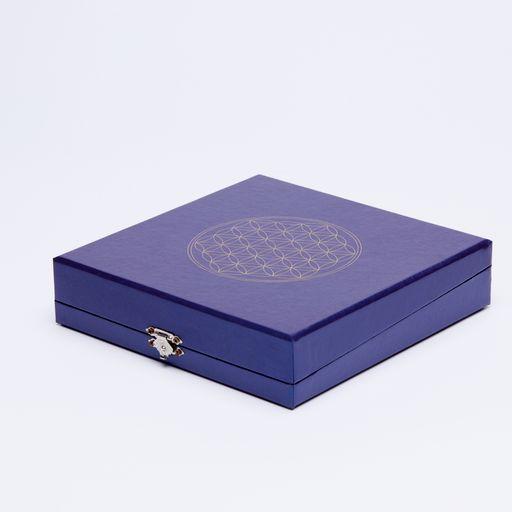

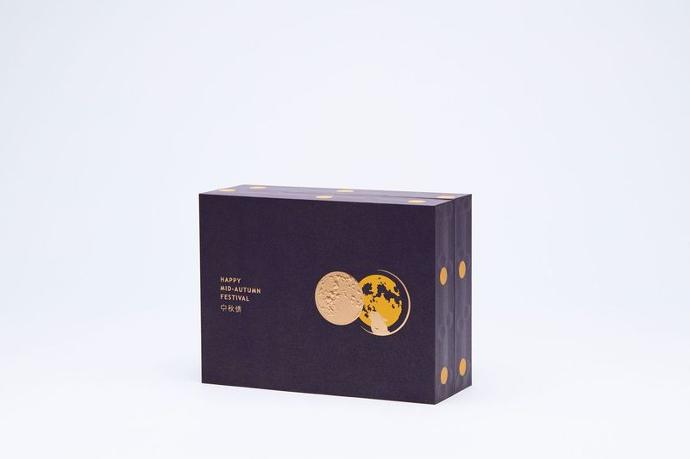

Gift Box

Gift boxes are an essential element for showcasing brand value and enhancing product image. Here are some emphasized special effects for gift boxes:

Hot foil stamping is a technique that involves applying metallic foil onto the surface of a gift box. It creates a luxurious and noble visual effect. Through hot foil stamping, you can add metallic elements such as brand logos, text, patterns, etc., to the gift box, making it more attractive and unique. The process involves using heat and pressure to transfer the foil onto the surface, creating a shiny and eye-catching design. Hot foil stamping adds a touch of elegance and sophistication to the gift box, making it stand out and leave a lasting impression.

Embossing is a processing technique that creates raised patterns or text on the surface of a gift box. Through embossing, you can highlight specific parts of the gift box, adding texture and a three-dimensional effect. This effect can make the gift box more refined and eye-catching, enhancing the overall tactile experience. Embossing involves using heat and pressure to reshape the material and create the raised design. It adds a sense of depth and elegance to the gift box, making it visually and tactilely appealing.

Lamination is a process of applying a thin layer of transparent film to the surface of a gift box. This film can enhance the glossiness, waterproofness, and durability of the gift box, while also protecting it from scratches or stains. Through lamination, the gift box can achieve a more vibrant and high-quality appearance. The film adds a smooth and shiny finish to the gift box, making it visually appealing and enhancing its overall presentation. Additionally, lamination provides an extra layer of protection, ensuring the gift box maintains its pristine condition during handling and transportation.

Spot gloss is a special optical effect applied to specific areas of a gift box, creating a shimmering or reflective effect. This effect enhances the visual appeal and adds a sense of detail to the gift box, making it more eye-catching and visually engaging. By selectively applying gloss to certain elements or patterns, the gift box gains a dynamic and multi-dimensional appearance, capturing attention and making a statement. The spot gloss effect adds depth and sophistication to the design, elevating the overall presentation of the gift box.

Ribbons and bows: Adding ribbons or bows to a gift box enhances its elegance and adds a touch of sophistication. This type of decoration elevates the overall aesthetic of the gift box, showcasing attention to detail. By incorporating ribbons and bows, the gift box exudes a sense of luxury and creates a more festive atmosphere, emphasizing the thoughtful presentation of the gift.

Transparent window: Adding a transparent window to a gift box allows for the display of the gift's contents, providing recipients with a clear view. This design element enhances the interactivity and attractiveness of the gift box. By incorporating a transparent window, the gift box not only showcases the thoughtfully chosen gift but also creates a sense of anticipation and excitement for the recipient.

Special die-cutting: By using special die-cutting techniques, gift boxes can be cut into specific shapes or patterns, adding uniqueness and artistic flair. This type of cutting allows the gift box to stand out from the crowd and highlight the brand's personality. Whether it's a custom shape that represents the product or a creative design element, special die-cutting adds an extra touch of creativity and aesthetics to the gift box, making it truly memorable.

Texture and patterns: Adding texture or patterns to the surface of gift boxes enhances visual depth and tactile sensation. This effect allows the gift box to have a richer texture and finer details. Whether it's a subtle embossed texture, a decorative pattern, or an intricate design, incorporating texture and patterns adds an extra dimension to the gift box, making it visually appealing and engaging to touch. The choice of texture and patterns can also align with the brand's aesthetic or complement the theme of the occasion, further enhancing the overall presentation of the gift box.

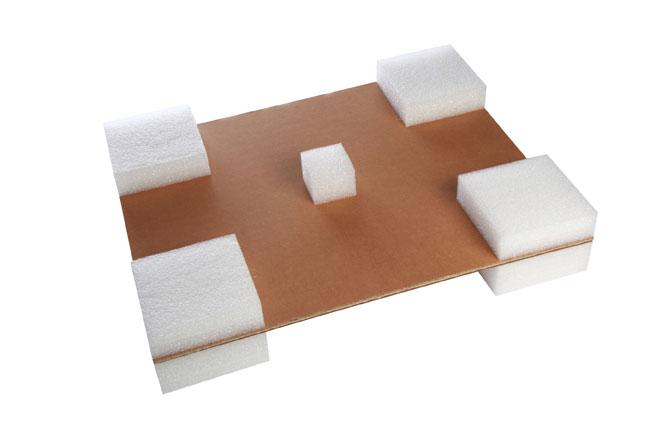

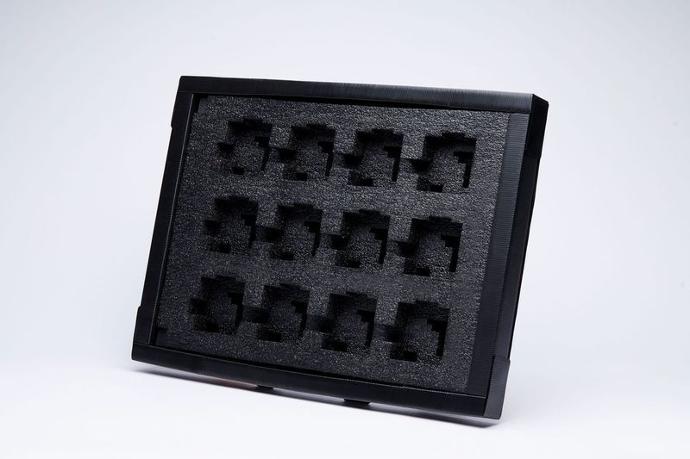

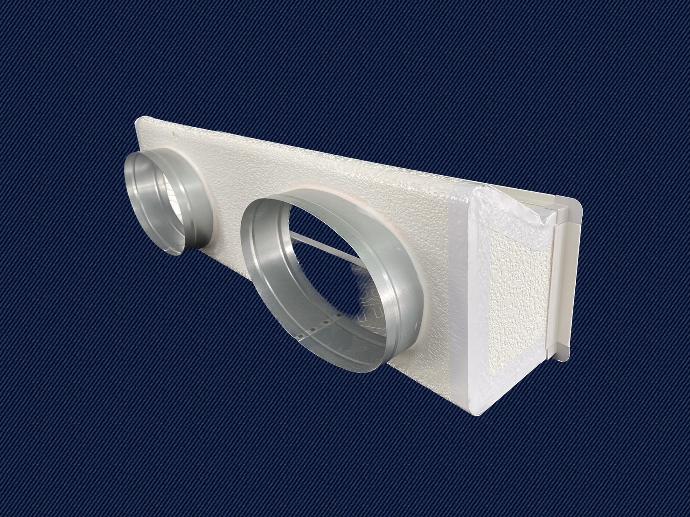

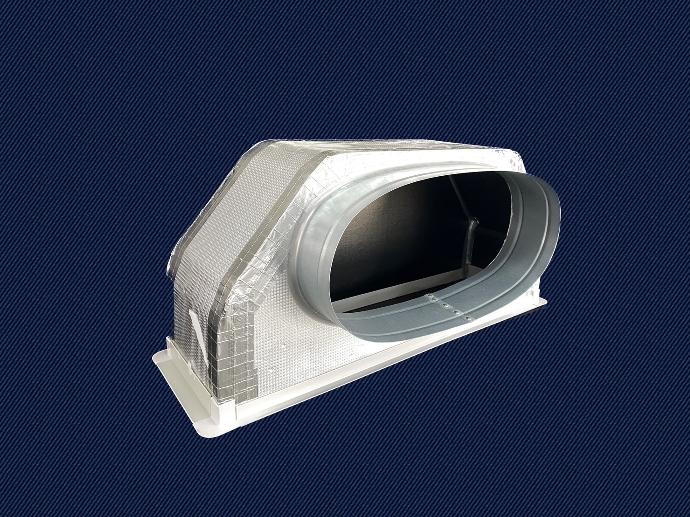

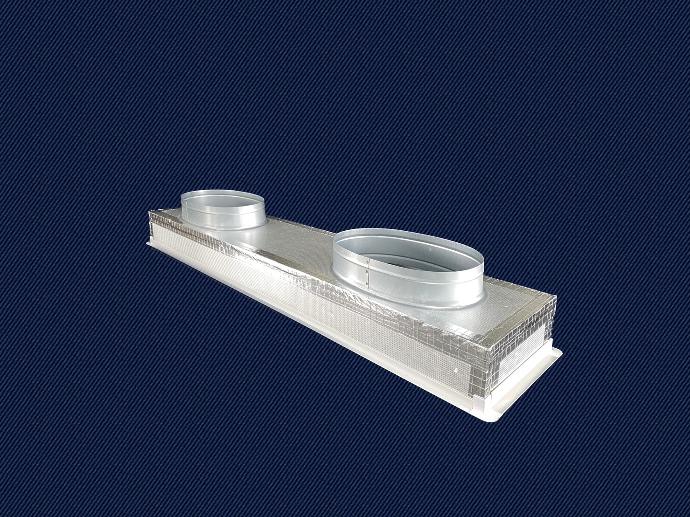

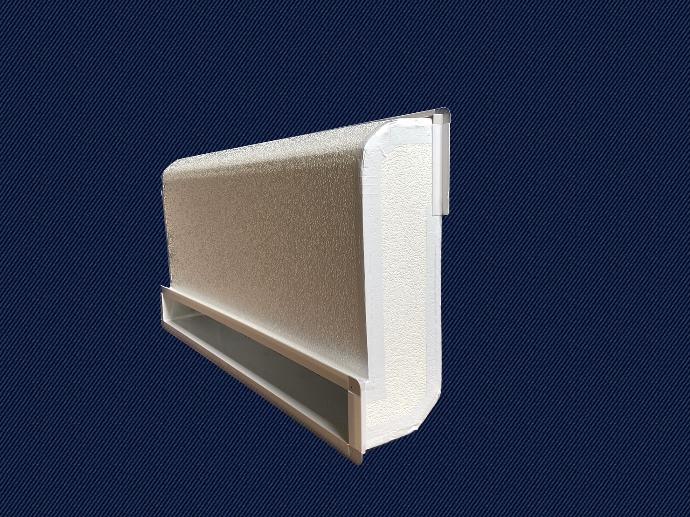

Heavy Packaging

Customizing multi-layer reinforced corrugated boards to provide optimal protection for heavy-duty and delicate machinery, large components, and other specialized products.