Consulting

Design

Sampling

Manufacture

Professional Consulting

Solving Packaging Issues: Our professional consulting team is able to identify and address various packaging issues, such as inadequate protective performance, improper sizing, damages during transportation, and more. We will leverage our extensive experience and industry knowledge to provide targeted solutions that ensure optimal packaging protection for your products.

Proposing Improvement Solutions: Our professional consulting team will propose innovative improvement solutions based on your needs and objectives to enhance packaging efficiency and performance. Through recommendations in optimizing packaging design, material selection, transportation methods, and more, we can help you reduce logistics costs and improve production efficiency.

Reducing Logistics Costs: We provide our clients with solutions to optimize logistics costs. By evaluating and analyzing factors such as transportation processes, packaging design, and material selection, we can offer recommendations to reduce packaging material usage, optimize transportation methods, and save on transportation costs, thereby reducing your overall logistics expenses.

Packaging Design

- Structural Design: We have a highly experienced team of structural designers who can create optimal packaging structures based on your product characteristics and requirements. We ensure that the packaging design provides maximum safety and stability for your products during transportation and storage. Our team will consider factors such as product dimensions, fragility, weight distribution, and handling requirements to design a packaging solution that offers the best protection for your products.

- 2D and 3D Animation Design: With our expertise in 2D and 3D design techniques, we can create realistic and visually appealing representations of packaging designs. This allows you to have a better understanding and evaluation of the packaging design during the design phase. The use of 2D and 3D animations helps in visualizing how the packaging will look in real life and provides valuable insights for product transportation and display. Our team can also provide practical recommendations based on the visualizations to optimize the packaging design for transportation and display purposes.

- Providing Transportation Recommendations: In addition to packaging design, we also specialize in providing transportation recommendations to our clients. Taking into account factors such as product characteristics, transportation distance, and destination, we offer the best transportation methods and packaging strategies to ensure the safety and efficiency of product transportation. Our expertise allows us to identify the most suitable shipping methods, handling requirements, and protective measures to minimize the risk of damage or loss during transit. By optimizing the transportation process, we aim to enhance the overall supply chain efficiency and customer satisfaction.

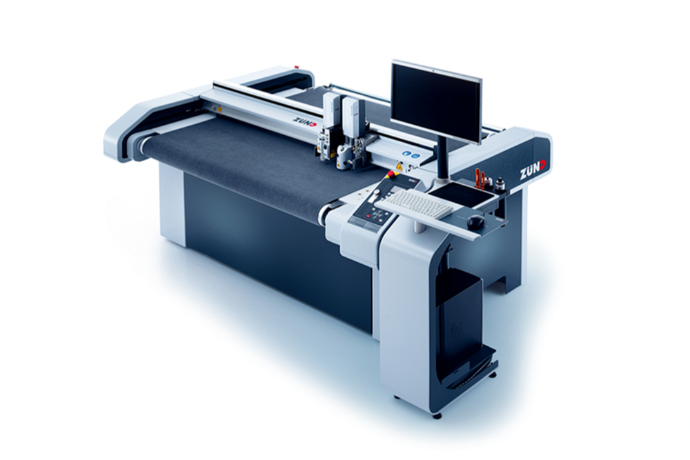

Digital Cutting

Rapid Delivery: With the use of digital cutting technology, we are able to quickly produce samples and prototypes, significantly reducing the time required compared to traditional manufacturing processes. This enables us to expedite product development and speed up time to market. By leveraging digital cutting technology, we can efficiently and accurately create packaging prototypes, allowing for faster iterations and adjustments based on client feedback. This expedited process ultimately enables us to deliver products to our clients in a timely manner, meeting their time-sensitive requirements and ensuring faster go-to-market strategies.

High Precision: Digital cutting technology offers a high level of precision, allowing us to achieve complex cutting and manufacturing requirements. With this technology, we can precisely create prototypes and samples that meet your design specifications. The high precision of digital cutting ensures that every detail of the packaging is accurately produced, resulting in high-quality samples and a perfect presentation of the final product. This level of precision is essential for maintaining consistency and meeting the exacting standards of our clients.

Flexibility and Versatility: Digital cutting technology offers flexibility and versatility in working with various materials and thicknesses, including cardboard, EPE (Expanded Polyethylene), foam, and more. This allows us to cater to different product sampling requirements and provide a wide range of solutions. Whether it's a rigid box, foam insert, or custom-shaped packaging, our digital cutting technology can handle diverse materials and deliver precise results. This flexibility enables us to meet the unique needs of our clients and offer customized solutions that are tailored to their specific products.

Testing laboratory

Drop testing: We conduct rigorous drop testing to ensure the durability and protective performance of our products during transportation and use.

Compression testing: We conduct compression testing to verify the product's ability to withstand pressure during stacking and transportation, ensuring that it can withstand the pressure generated during stacking and protect the internal items from being crushed or deformed.

Burst strength testing: We conduct burst strength testing to ensure that the cardboard has sufficient strength to withstand pressure, impacts, and other stresses, thereby ensuring that the product can withstand these forces effectively.

We adhere to the RoHS (Restriction of Hazardous Substances) regulations and employ a halogen-free manufacturing process to ensure that our products comply with environmental and health safety standards.

Smart Manufacture

Smart Manufacturing: We leverage smart manufacturing technologies to integrate digitization and automation into our production processes. This allows us to enhance production efficiency, reduce error rates, and ensure consistent and accurate product quality. Through smart manufacturing, we can more flexibly respond to customer demands and achieve highly efficient production workflows.

Comprehensive Quality Management: We implement a comprehensive quality management system that covers every aspect of our operations, from the selection of raw materials to the monitoring of production processes. Our aim is to ensure that our products meet high-quality standards. We conduct rigorous inspections, testing, and quality control measures to ensure that each product meets our customers' requirements and expectations.

On-time Delivery: We prioritize our customers' delivery timelines and strive to accommodate their time requirements. Through optimized production planning and control of our manufacturing processes, we ensure that orders are completed on time and delivered punctually to our customers.